November 1, 2013

by Richard Maurer

Published in PHC News, November 2013

Custom tiled showers are very popular, especially with up-scale baby boomers who want their homes to reflect the quality, function, and style they desire. A beautiful, custom shower can be a handsome addition to any home and may add substantial value to the property. In this article we will explore some of the issues to consider when planning, designing, and building tiled showers.

Waterproofing is especially important since leaks can result in catastrophic damage and financial loss. Additionally, there is generally a great deal of inconvenience and aggravation associated with the failures of waterproofing systems. Leaks and other risks can be avoided by selecting appropriate products for your application, following proper installation methods, adhering to industry standards and plumbing code requirements.

In order to create a shower that meets your specific needs, you need to consider a variety of issues (e.g. how much space is available, will the shower be over occupied space, how much water will the shower generate, physical limitations, etc.). If you would like to stay in your home and “age in place”, you may want to design a shower without a curb. In addition to easy access, barrier free showers facilitate contemporary designs popular with up-scale owners.

The following comments are common to all showers:

- Shower must be waterproof to avoid leaks and damage to ceilings and rooms below.

- In order to prevent mold, water and vapor must be prevented from penetrating shower walls.

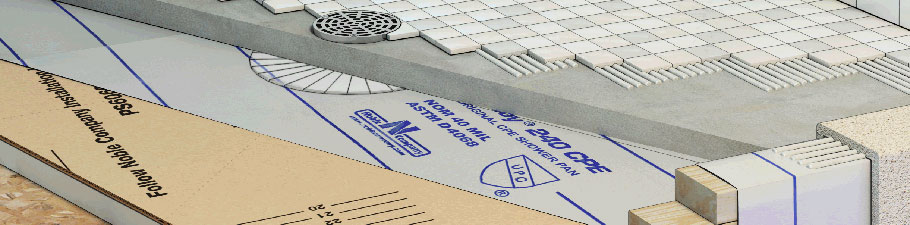

- Water must drain so the waterproofing membrane installed on floors must be sloped at least ¼” per foot to a drain. The slope should be made from a solidly formed material, structurally strong enough to support load requirements. Dry pack mortar is the traditional product for that application, but there are a variety of commercial products available for both traditional and thin-bed (bonded) waterproofing membranes. For example, PRO-SLOPE™ creates a slope for traditional shower pan liners. Noble Company, Laticrete, and various others offer pre-sloped bases that are waterproof and ready to be tiled.

- The drain must be tied to the waterproofing membrane, and if the drain has weep holes, they must be protected from clogging.

- Your waterproofing system must be durable. Ideally, it will last as long as the tile (which could be 50 years).

- The waterproofing is generally inspected by a plumbing inspector. Therefore, products and methods must be accepted by the local plumbing code authority.

Custom tiled showers can be waterproofed using a traditional mortar bed method with a waterproofing membrane (shower pan liner) installed under a mortar bed. Showers can also be waterproofed with a thin-bed membrane where the membrane is bonded to the sloped substrate Tile can be bonded directly to the membrane so a mortar bed above the membrane is not required. Thin-bed methods are lower in height and weight and are generally preferred for barrier free installations.

Sloping to traditional shower drains requires multiple arcs which precludes the use of large-format tiles. However, linear or trench drains use a single-slope so large tiles can be used. This feature enhances design flexibility and can result in spectacular looking showers with the latest large-format tile designs.

While linear drains are common in Europe, they are relatively new to the US. There are a number of companies producing linear drains and a variety of ways in which waterproofing is accomplished. Some things to consider when selecting linear drains include the following:

- The type of membrane used to waterproof the installation. Given the importance of a watertight installation, only the best is good enough.

- How does the drain connect to the waterproofing membrane and the waste system? Connections must be secure to ensure a watertight installation.

- How much water will the drain handle, which is typically expressed in gallons per minute (GPM)?

- How much height will the drain require? This would be a measure of the height of the drain plus height needed to attach the drain to the waste pipe, and mortar needed to support tile installation.

Some popular brands of linear drains include FreeStyle Linear Drains™, Kerdi Drain, Quartz, Proline, and Hydro Ban Drains. All models are made from stainless except for FreeStyle which is made from PVC or ABS plastic. FreeStyle Drains provide assurance of a watertight installation. The shower waste pipe is solvent welded directly into a hole in the bottom of the drain. And, FreeStyle is the only linear drain with a clamping collar mounted to the top of the drain to secure the waterproofing membrane to the drain.

Shower waterproofing generally requires approval by a plumbing inspector. There are two national plumbing codes: The International Plumbing Code (IPC) and the Uniform Plumbing Code (UPC). Some states have their own code requirements, but most model their code after one of the national codes. Drains should have approvals identified by IPC and/or UPC listings. Regardless of the type of drain you intend to use, confirm approval with local code authorities before installing.

If you plan on having a multi-spray shower system, select a drain that can handle the water flow. Manufacturers generally publish that information in gallons per minute (GPM). Drain capacities typically range from 8 to 36 GPM. FreeStyle’s capacity is 36.

Another suggestion is to extend waterproofing in the shower to the rest of the bathroom. If you are going to install new tile in the area, it is a reasonable addition in terms of time and cost and will increase the level of protection.

Waterproofing membranes generally come in one of 3 types: trowel applied, liquid, or sheet membranes. Sheet membranes offer uniform thickness and quality. They arrive at the jobsite as a membrane that is ready to install. They are generally packaged in rolls and come in different widths ranging from 39” to 72”. Wider widths can result in fewer seams which can reduce risk. Liquid and trowel applied membranes require the installer to control thickness which is essential for proper performance.

Unless you intend to redo your shower periodically, durability is critical. Noble sheet membranes are made from CPE which lasts as long as the tile, holds a crease, and have very low permeation rates. Permeation rates are a measure of how much water gets through the membrane. Lower rates are better. According the Tile Council of North America (TCNA), the perm rating should be < 0.5 perms for a membrane to be a vapor barrier.

Some sheet membranes can “bridge” movement joints in concrete floors. That is especially important when waterproofing larger areas like the bathroom outside the shower.

Liquid applied and “trowelable” membranes typically require fabric to support stressed areas (like changes in planes or attaching to drains). Liquid membranes are often preferred for waterproofing nooks, crannies and hard to reach areas.

While there are pros and cons to both types of membranes, showers generate more water than any rainforest so waterproofing is critical. Sheet membranes are uniform and thickness is not affected by imperfect substrates or differences in installers’ techniques. Strength, uniformity, and control of variables make sheet membranes the choice for many.

Many custom showers include benches and niches (recesses in walls to store shampoo). It is important to note that these elements must be waterproofed and that can be difficult. A number of preformed niches, benches, and curbs that are waterproof and ready to be tiled are available. These products save time and can significantly reduce potential problems. Noble Company produces a large variety of shapes and sizes of niches, benches and curbs.

Whether you are designing or constructing, consider the thoughts above and you can create a beautiful shower with the features you want that will remain watertight for decades.

®Registered Trademark of Noble Company, Grand Haven, MI | ™Trademark of Noble Company